Manufacturing

Manufacturing

René FERRARINI machines 2500 tons of materials per year.

With more than 50 years of experience, our expertise in the machining of stainless steel, aluminum, steel, brass and copper alloy is recognized throughout the industry.

René FERRARINI provides its customers with equipment adapted to all needs.

Numerical and multi-numerical bar turning

Our 8 numerically controlled multi-spindle machines and our 25 digital moving dolls are the preferred equipment for the medium or large series, ensuring high competitiveness and a high level of quality. They allow the machining of finished parts with a diameter ranging from 2 mm up to 32 mm in complex materials.

Escomatic bar turning

Our fleet of 40 escomatic machines is ideal for parts from Ø 0.5 to 6 mm. Escomatic towers make it possible to work all metals from wires and crowns. This technology is preferred for large and very large series.

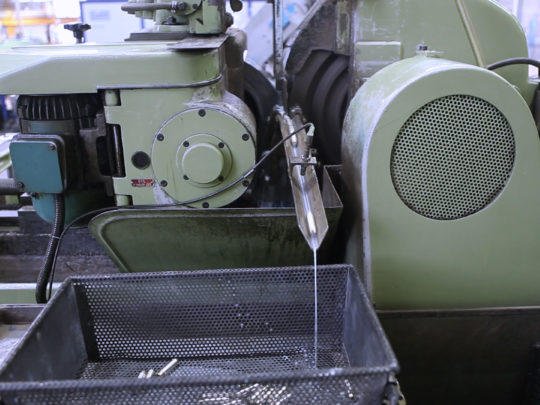

Mult-spindle bar turning

Our 40 multi-spindle machines are ideal for medium-sized parts from Ø 4 to 22 mm. Multi-spindle machines offer very short cycle times, which makes them specialized in large series. This technology guarantees excellent productivity.

Grinding

The machine park of the rectification sector is composed of 6 grinding machines, it allows to master internally the main professions of rectification (enfilade and centerless).

Camera and laser monitoring machines

Our strategy of integrating 100% final control has increased our quality performance. We now offer several control solutions: Dimensional control by camera, Aspect control by camera, Dimensional control by sensor, Laser control, Pressure leakage control.